Styrofoam transformations experimental prototypes in recycled polystyrene

Styrofoam Transformations: Experimental Prototypes in Recycled Polystyrene

Polystyrene, commonly known as Styrofoam, has long been a symbol of disposable convenience. Yet, its environmental impact is staggering, with millions of tons ending up in landfills and oceans each year. In response, designers and architects are pioneering experimental prototypes that repurpose recycled polystyrene into innovative, sustainable solutions. These transformations are not just about reducing waste; they are redefining materiality in contemporary design.

The Problem with Polystyrene Waste

Polystyrene is one of the most problematic plastics in terms of waste management. Its lightweight nature makes it easily airborne, contributing to urban pollution and marine debris. Moreover, traditional recycling methods are costly and inefficient, leading to low recycling rates. As cities strive for zero-waste architecture, the need for innovative reuse strategies has never been more urgent.

Transforming Waste into Design

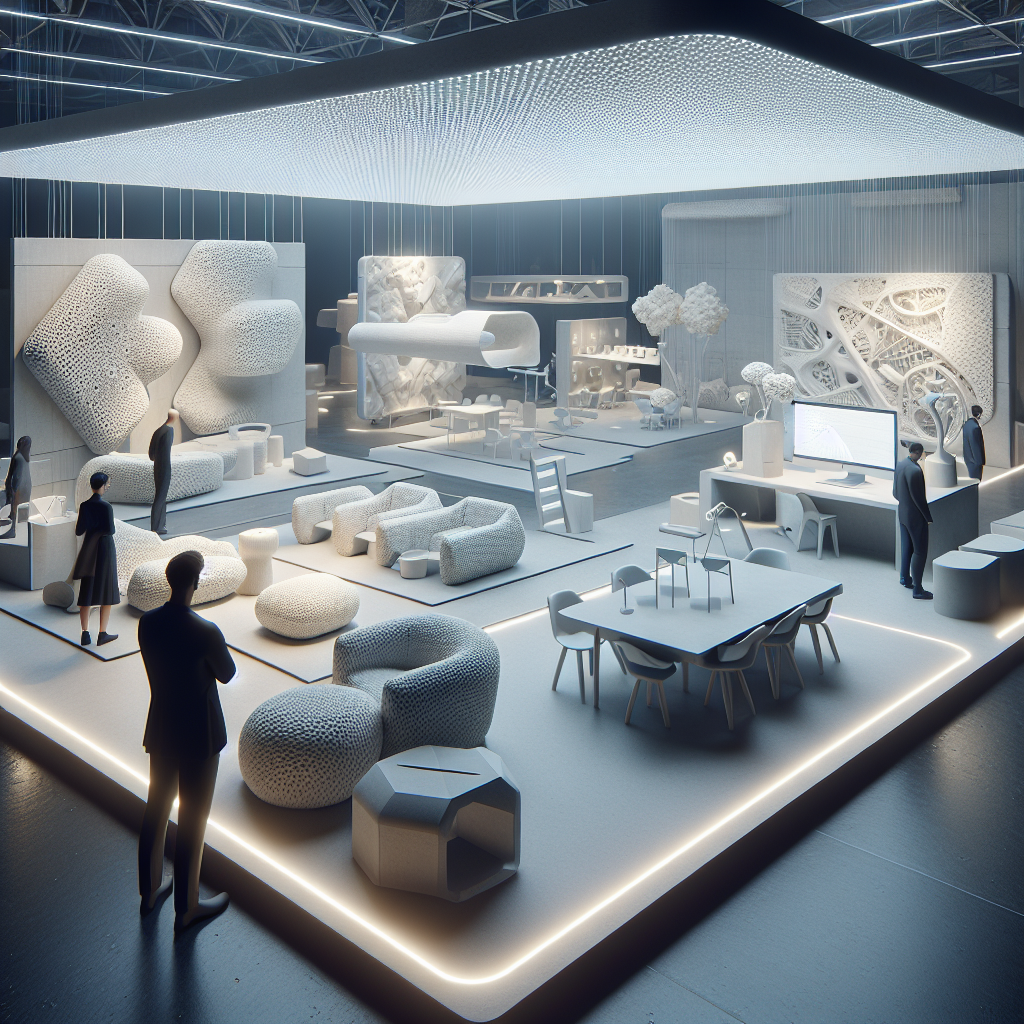

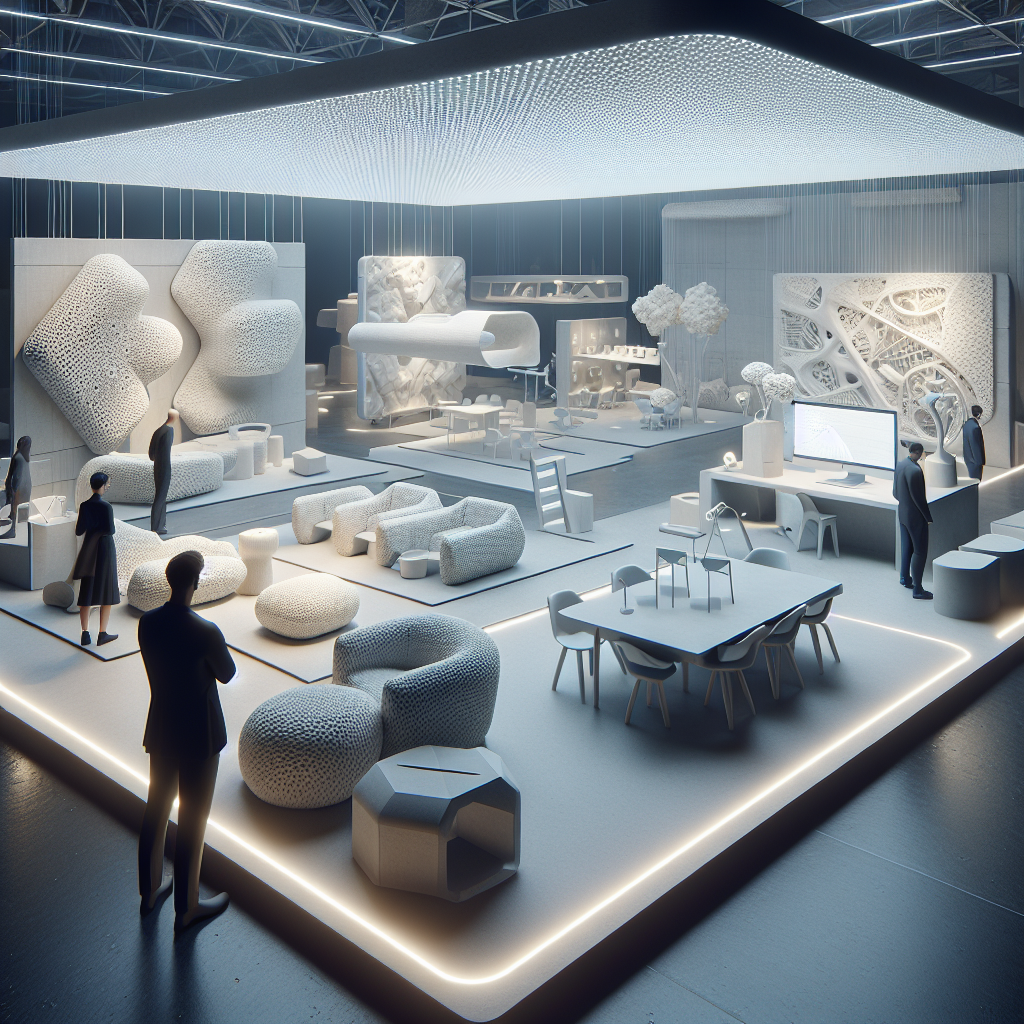

Recent advancements in material science have enabled the transformation of recycled polystyrene into functional and aesthetically compelling prototypes. Through processes such as heat compression, 3D printing, and chemical reformulation, designers are creating everything from 3D-printed structures to lightweight furniture and acoustic panels.

One notable example is the work of Dutch designer Dirk Vander Kooij, who has developed furniture pieces using extruded polystyrene. His process involves melting down discarded Styrofoam and reforming it into durable, sculptural seating. Similarly, researchers at MIT have explored upcycling techniques that turn polystyrene waste into insulation panels with high thermal efficiency.

Architectural Applications of Recycled Polystyrene

Beyond furniture, recycled polystyrene is making its way into architectural applications. Some firms are experimenting with polystyrene-based insulation, which offers excellent thermal properties while reducing the demand for virgin materials. In Japan, architects have integrated compressed polystyrene blocks into earthquake-resistant housing, leveraging the material’s lightweight yet resilient nature.

Moreover, in the realm of biophilic design, polystyrene is being repurposed into green wall structures that support plant growth. These applications not only reduce waste but also contribute to energy-efficient and environmentally responsive architecture.

The Role of Digital Fabrication

Digital fabrication technologies, such as CNC milling and robotic extrusion, are playing a crucial role in the reinvention of polystyrene. By using computational design, architects can create intricate forms that were previously impossible with traditional materials. This approach aligns with the principles of parametric design, where algorithms dictate material distribution, optimizing strength and efficiency.

For instance, the Italian design studio Carlo Ratti Associati has developed a system that converts polystyrene waste into modular building components. These components can be assembled into temporary pavilions, exhibition spaces, or even emergency shelters, showcasing the potential of recycled materials in sustainable design.

Challenges and Future Prospects

Despite these promising developments, challenges remain. One of the biggest hurdles is the contamination of polystyrene waste, which complicates the recycling process. Additionally, public perception of recycled materials as inferior to virgin alternatives continues to be a barrier to widespread adoption.

Yet, as the design industry increasingly embraces circular economy principles, the potential for polystyrene transformations will only grow. With continued research and investment, recycled polystyrene could become a mainstream material in architecture and product design, shifting the narrative from waste to resource.

Conclusion

The transformation of Styrofoam waste into high-performance design elements is more than an environmental necessity—it is a creative revolution. By leveraging cutting-edge fabrication techniques and rethinking material applications, designers are proving that even the most problematic plastics can have a second life. As these experimental prototypes gain traction, they offer a glimpse into a future where waste is not discarded but reimagined.