Disassembly geometry design: for easy breakdown and recycling

Disassembly Geometry Design: The Future of Architecture Built for Easy Breakdown and Recycling

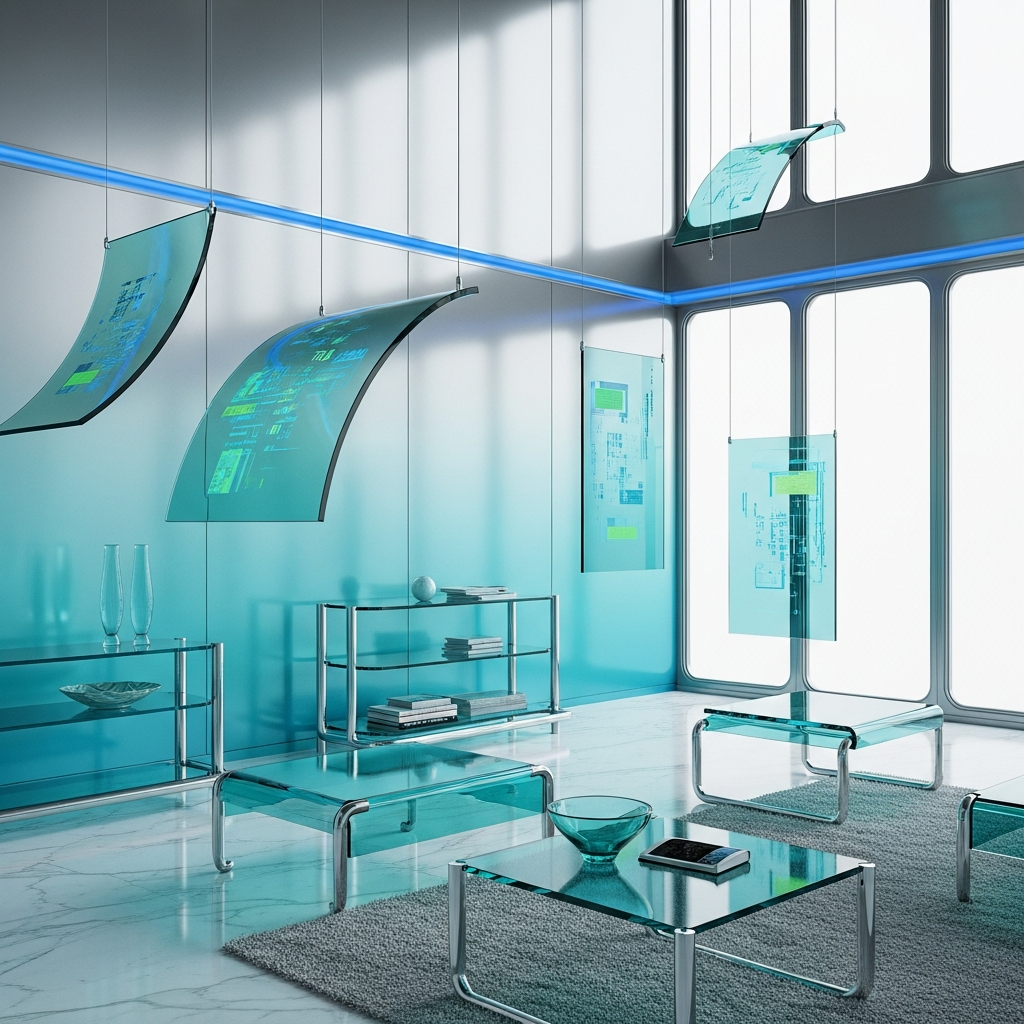

In an era defined by circular economy principles and material consciousness, a new design philosophy is emerging at the intersection of architecture, sustainability, and engineering: disassembly geometry design. This approach reimagines how buildings, interiors, and products are conceived—not as static, permanent entities, but as dynamic systems designed for graceful deconstruction. It’s a shift from building for endurance to building for intelligent impermanence, where every joint, panel, and fastener anticipates its own eventual release back into the material cycle.

The Geometry of Reversibility

At its core, disassembly geometry design is a discipline that applies geometric logic to facilitate the easy breakdown of structures. Unlike traditional construction, which often relies on adhesives, composites, or welded joints that make recycling difficult, this method employs modular geometries, reversible connections, and standardized components. The result is architecture that can be dismantled as elegantly as it was assembled.

In practice, this means designing with mechanical interlocks—precision-engineered joints that snap, slide, or rotate into place without permanent bonding. The approach draws inspiration from both Japanese joinery and modern digital fabrication techniques, merging ancient craftsmanship with computational precision. Each component’s geometry is optimized not only for structural integrity but also for its ability to be separated, sorted, and reused.

“We’re moving from the idea of demolition to disassembly,” notes Dutch architect Thomas Rau, a pioneer in circular design. “Buildings should be treated as material banks, not waste generators.” This philosophy aligns with the European Union’s Circular Economy Action Plan, which encourages industries to design for reuse and recyclability from the outset.

Designing for Circularity: A New Architectural Paradigm

The global construction industry is responsible for nearly 40% of carbon emissions, according to the United Nations Environment Programme. The majority of this impact stems from material extraction and disposal. Disassembly geometry design directly addresses this by ensuring that materials retain their value beyond a building’s lifespan.

Architects and designers are increasingly integrating this thinking into their workflows. Projects like the Triodos Bank Headquarters in the Netherlands exemplify this shift. Designed by RAU Architects, the building was conceived as a “kit of parts” that can be fully disassembled and reassembled elsewhere. Every beam, panel, and joint was digitally catalogued in a material passport, enabling future generations to understand its composition and reuse potential.

This approach echoes the principles explored in zero-waste architecture, where waste is eliminated through thoughtful design. The geometric precision of disassembly ensures that components can be separated without damage, preserving their material integrity for future applications.

Material Intelligence and Modular Thinking

Geometry plays a crucial role in this transformation. The angle of a joint, the curvature of a panel, or the tolerance of a fastener can determine whether a structure is recyclable or destined for landfill. Designers are now using parametric modeling tools to simulate disassembly sequences, ensuring that every element can be removed in reverse order of assembly.

In furniture and interior design, this principle manifests in modular systems that adapt to changing needs. Consider the “snap-fit” furniture trend—tables, shelves, and partitions that can be assembled without tools and reconfigured endlessly. This echoes the ethos of modular design, where flexibility and longevity replace disposability.

Material selection is equally critical. Fast-growing materials like bamboo, recycled aluminum, and engineered timber are favored for their renewability and ease of separation. The rise of timber in high-rise construction demonstrates how natural materials can align with disassembly principles, offering both structural performance and ecological responsibility.

Case Studies: Disassembly in Action

Several pioneering projects around the world are demonstrating the power of disassembly geometry design:

- OMA’s Reversible Pavilion – Built for a temporary exhibition in Rotterdam, this structure used interlocking aluminum panels that could be flat-packed and reused. The geometry was derived from tessellated polygons, ensuring both stability and efficient disassembly.

- ETH Zurich’s DFAB House – A research project exploring robotic construction, where each component was digitally fabricated for precise fit and future reversibility. The building serves as a prototype for circular construction systems.

- Carlo Ratti Associati’s Circular Pavilion – Constructed from recycled scaffolding tubes, the pavilion could be dismantled in hours. Its geometric logic allowed every component to return to the construction supply chain.

These examples illustrate how geometry can be a language of sustainability—an invisible code embedded in the form of a building that dictates its future adaptability.

Digital Tools and the Future of Disassembly

The digital revolution is amplifying the potential of disassembly geometry. Building Information Modeling (BIM) now integrates material passports and lifecycle data, allowing architects to simulate not only how a building is constructed but also how it will be taken apart. This predictive modeling transforms the design process into a circular narrative, where the end of one structure becomes the beginning of another.

Parametric design tools, as explored in algorithmic architecture, are being used to generate complex geometries that optimize both assembly and disassembly. These systems can analyze stress points, connection sequences, and material behavior, ensuring that each component can be reused with minimal intervention.

Emerging technologies such as robotic disassembly and AI-driven sorting systems are also entering the conversation. In Japan, robotic arms are being tested to dismantle modular housing units, identifying materials through embedded QR codes. This convergence of geometry, data, and automation signals a profound shift toward intelligent circular architecture.

Emotional Durability and the Aesthetics of Reuse

Beyond technical efficiency, disassembly geometry design invites a new aesthetic sensibility—one that celebrates impermanence and transformation. The visible joints, exposed fasteners, and modular seams become part of the visual language, communicating honesty and adaptability. It’s a design ethos that aligns with the Wabi-Sabi aesthetic, where beauty lies in change and imperfection.

Designers are also exploring how emotional attachment can extend a product’s life. When users understand that their furniture or building can evolve with them—reconfigured, repaired, or relocated—it fosters a deeper connection and reduces the impulse to discard. This emotional durability complements material durability, forming a holistic approach to sustainability.

Challenges and Opportunities Ahead

Despite its promise, disassembly geometry design faces several challenges. The construction industry’s reliance on composite materials and permanent adhesives remains a major barrier. Economic incentives for reuse are still limited, and building codes often lag behind innovation. Yet, as environmental regulations tighten and resource scarcity intensifies, the value proposition of reversible design becomes undeniable.

Forward-thinking firms are already integrating disassembly principles into their workflows, seeing it not as a constraint but as a creative opportunity. The next generation of architects and designers will likely treat reversibility as a fundamental design parameter—just as structure, light, and form are today.

A Blueprint for Regenerative Design

Disassembly geometry design is more than a technical strategy; it’s a philosophical shift in how we conceive built environments. It challenges the notion of permanence and invites us to see architecture as a living system—capable of growth, adaptation, and renewal. By embedding reversibility into geometry, designers are crafting a new language of sustainability that transcends trends and technologies.

As the world moves toward net-zero goals and material circularity, this approach offers a tangible path forward. It transforms waste into resource, obsolescence into opportunity, and design into a regenerative act. In this emerging paradigm, the beauty of a building lies not only in how it stands—but in how gracefully it can come apart.

For those seeking to explore the broader implications of circular and sustainable design, related readings such as biodegradable architecture and circular economy design offer deeper insights into how geometry, material science, and ethics are converging to redefine the built world.