3D-Printed Bridges: The Future of Infrastructure, Built by Robots

3D-Printed Bridges: The Future of Infrastructure, Built by Robots

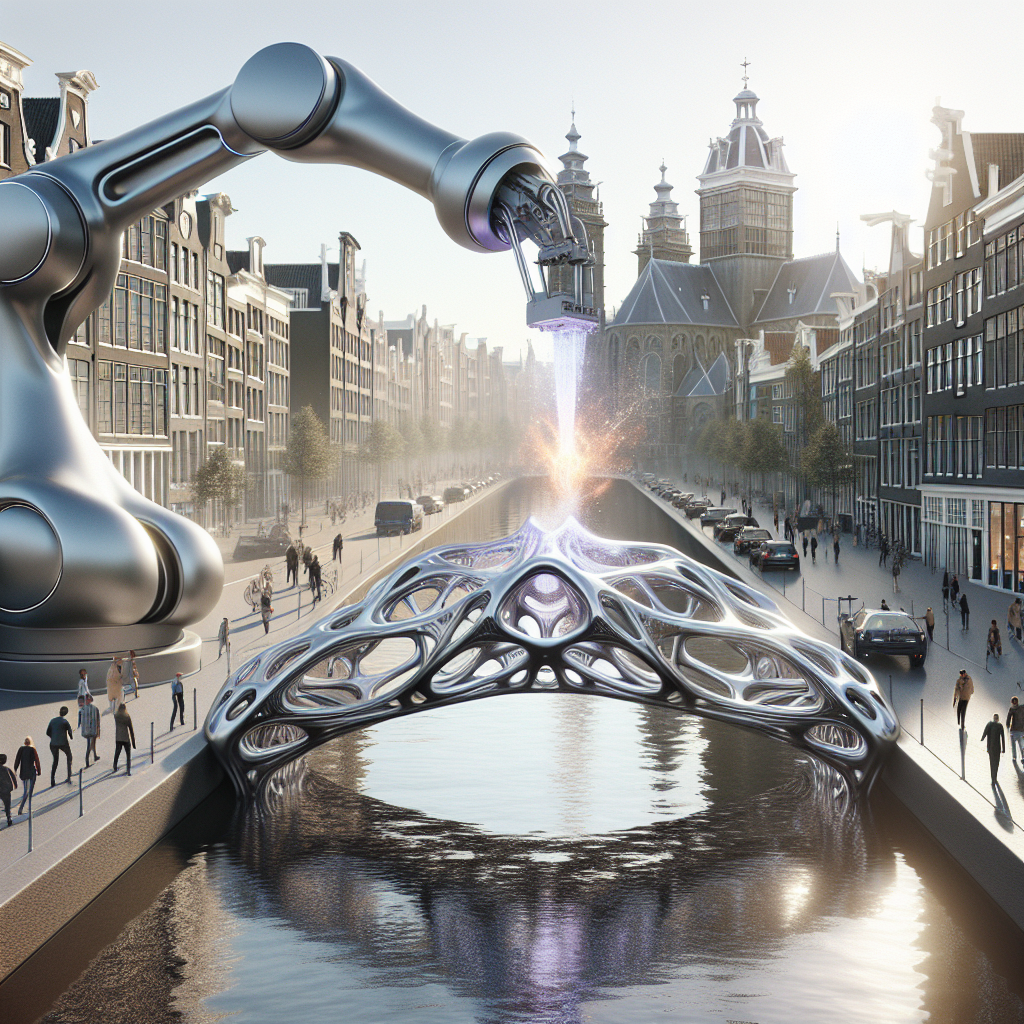

In the heart of Amsterdam, a silvery, sinuous structure stretches across the Oudezijds Achterburgwal canal. It gleams under the Dutch sun like a strand of liquid metal — yet it wasn’t welded, riveted, or cast in the traditional sense. Instead, it was printed. Layer by layer, robotic arms extruded molten stainless steel to form the world’s first 3D-printed bridge, a project by MX3D that has since become a symbol of a new era in architecture and infrastructure. The age of 3D-printed bridges — structures conceived by algorithms and built by robots — has arrived, reshaping how we think about construction, sustainability, and design itself.

The Rise of Robotic Construction

For decades, bridge building has been a feat of human engineering, reliant on heavy machinery, manual labor, and complex logistics. Today, that paradigm is shifting. 3D printing in architecture — once confined to experimental pavilions and small-scale prototypes — is now tackling one of the most symbolically and structurally demanding typologies: the bridge. The technology’s promise lies in its precision, efficiency, and adaptability. Robots can print intricate geometries impossible to achieve with traditional methods, using only the exact amount of material required, reducing waste dramatically.

According to a 2025 report by the World Economic Forum, additive manufacturing in construction could reduce material waste by up to 60% and cut project timelines by half. These efficiencies are not just technical; they are environmental imperatives. As cities worldwide strive toward net-zero construction, robotic fabrication offers a tangible route to lower carbon emissions and smarter resource use.

Case Studies: From Amsterdam to Shanghai

The MX3D Bridge in Amsterdam, completed in 2021, remains the most iconic example of this emerging typology. Designed by Joris Laarman Lab and engineered with Arup, the bridge was printed using six-axis robotic arms that deposited stainless steel in mid-air, guided by generative algorithms. The result is a sculptural, organic form that seems to have grown rather than been assembled — a visual language that aligns with the parametric design movement dominating contemporary architecture.

In Shanghai, the world’s largest 3D-printed concrete bridge — spanning 26.3 meters — was unveiled by Tsinghua University’s School of Architecture. Printed in just 450 hours, it used recycled concrete aggregates and required no traditional formwork. Its undulating parapets and biomimetic structure recall the branching patterns of tree roots, embodying a new aesthetic of structural minimalism — where every curve serves both form and function.

Meanwhile, in Spain, researchers at the Institute of Advanced Architecture of Catalonia (IAAC) have been experimenting with 3D-printed pedestrian bridges made from biodegradable materials, exploring the intersection of biodegradable architecture and infrastructure. These prototypes suggest a future where bridges might one day decompose naturally, leaving no trace behind — a poetic inversion of permanence in civil engineering.

How Robots Are Redefining Craft

At first glance, the notion of robots “crafting” architecture might seem paradoxical. Yet the most compelling 3D-printed bridges are not merely feats of automation; they are expressions of digital craftsmanship. The robotic arms that print these structures operate with a precision that rivals — and in some ways extends — the artisan’s hand. They follow digital scripts derived from parametric models, adjusting in real time to environmental data, material behavior, and structural feedback.

This new relationship between designer and machine echoes the spirit of the Bauhaus movement, which sought harmony between art, craft, and technology. Today’s architects are programming rather than chiseling, but the ethos remains: design as a synthesis of human intuition and technological capability. The bridge, once a symbol of human ingenuity, now becomes a symbol of collaboration between human and machine.

Material Innovation and Sustainability

Material science is at the core of this revolution. From stainless steel to geopolymer concrete and even sand-based composites, 3D printing enables the use of unconventional materials that can be locally sourced and recycled. Researchers are exploring the potential of sand printing technology to create bridges in desert regions, leveraging abundant natural resources while minimizing transportation emissions.

Some projects integrate sensors directly into the printed material, creating “smart bridges” capable of monitoring their own structural health. Embedded fiber optics and strain gauges collect data on stress, vibration, and temperature, feeding into digital twins — virtual replicas that evolve alongside their physical counterparts. This integration of data and design aligns with the broader movement toward AI-driven architecture, where predictive maintenance and adaptive performance become standard features of infrastructure.

Design Language: Organic Geometry Meets Algorithmic Logic

Visually, 3D-printed bridges are rewriting the language of infrastructure. Their forms often evoke natural morphologies — coral reefs, bone structures, or flowing water — because they are generated through algorithms that mimic natural growth processes. This aesthetic shift marks a departure from the rectilinear rigidity of industrial modernism toward a more fluid, biomorphic expression of structure.

In the Amsterdam bridge, the stainless-steel lattice undulates like a living organism, reflecting light in rippling patterns that change with the viewer’s movement. In contrast, the Shanghai bridge’s concrete ribs cast rhythmic shadows that animate the pedestrian experience. These are not merely bridges to cross; they are experiences to inhabit — sculptural gestures that merge engineering with artistry.

Challenges and the Road Ahead

Despite its promise, 3D-printed infrastructure faces significant challenges. Regulatory frameworks have yet to catch up with the technology, and questions remain about long-term durability, scalability, and maintenance. The cost of robotic systems and specialized materials can still be prohibitive for large-scale deployment. Yet, as with early experiments in 3D-printed housing, costs are falling rapidly as technology matures and adoption widens.

Another challenge lies in the cultural perception of automation. For many, the idea of robots constructing public infrastructure raises questions about labor displacement and authenticity. Yet proponents argue that automation does not replace human creativity — it amplifies it. By delegating repetitive, hazardous, or precision-intensive tasks to machines, architects and engineers can focus on conceptual innovation, sustainability, and design quality.

Bridging the Future

3D-printed bridges are more than feats of engineering; they are philosophical statements about the future of design. They challenge our assumptions about permanence, authorship, and the relationship between nature and technology. In their flowing geometries and algorithmic logic, they embody a new kind of beauty — one born from data, yet deeply human in its ambition to connect.

As cities grapple with the twin pressures of urbanization and climate change, the fusion of robotics, digital fabrication, and sustainable materials offers a compelling blueprint for the next generation of infrastructure. These bridges — printed, not built — stand as testaments to a future where architecture is not just constructed, but grown through code, collaboration, and creativity.

In the shimmering reflection of Amsterdam’s canal, the MX3D Bridge reminds us that innovation often begins with a single crossing — a leap from the known to the possible. The future of infrastructure is already under construction, one printed layer at a time.

Keywords: 3D-printed bridges, robotic construction, digital fabrication, sustainable infrastructure, parametric design, AI in architecture, additive manufacturing, smart bridges, future of construction, biodegradable architecture.

Published on 01/23/2026