3D-printed cartilage in design: biomimicry approach to flexible interiors

3D-Printed Cartilage in Design: A Biomimicry Approach to Flexible Interiors

In the evolving landscape of architecture and interior design, biomimicry has become more than a philosophy—it’s a methodology reshaping how we conceive and construct spaces. Among the most fascinating frontiers in this movement is the exploration of 3D-printed cartilage-inspired materials. Borrowing from the flexibility, resilience, and self-healing properties of biological cartilage, designers and architects are now envisioning interiors that move, adapt, and respond much like living organisms. This convergence of biology, technology, and design signals a profound shift toward a new material intelligence—one that prioritizes adaptability, sustainability, and human comfort.

The Rise of Biomimetic Materials in Architecture

Biomimicry—the practice of emulating nature’s strategies to solve human challenges—has long influenced architecture, from ancient vernacular designs to cutting-edge parametric structures. Yet, the current wave of innovation is more material than metaphorical. Researchers and designers are turning to bioengineered tissues and synthetic cartilage analogues to inspire new forms of spatial flexibility. Unlike static walls or rigid partitions, these materials promise interiors that can flex, absorb impact, and reshape themselves in response to environmental or human stimuli.

This approach aligns with the broader trend of biomimicry in design, where the emphasis is shifting from imitation to integration. Instead of merely copying nature’s forms, designers are now embedding its principles into the very material logic of buildings. The result: interiors that breathe, bend, and behave more like living tissues than inert structures.

Cartilage as a Design Blueprint

Cartilage is a remarkable biological material—strong yet flexible, capable of withstanding pressure while maintaining its form. It owes these properties to its collagen fiber network and the fluid-filled matrix that allows it to deform and recover seamlessly. Translating this into architecture, 3D-printed cartilage-inspired materials can be engineered using polymers, hydrogels, and bioresins that mimic this microstructure. These synthetic composites can flex under stress, return to their original shape, and even self-repair minor damage.

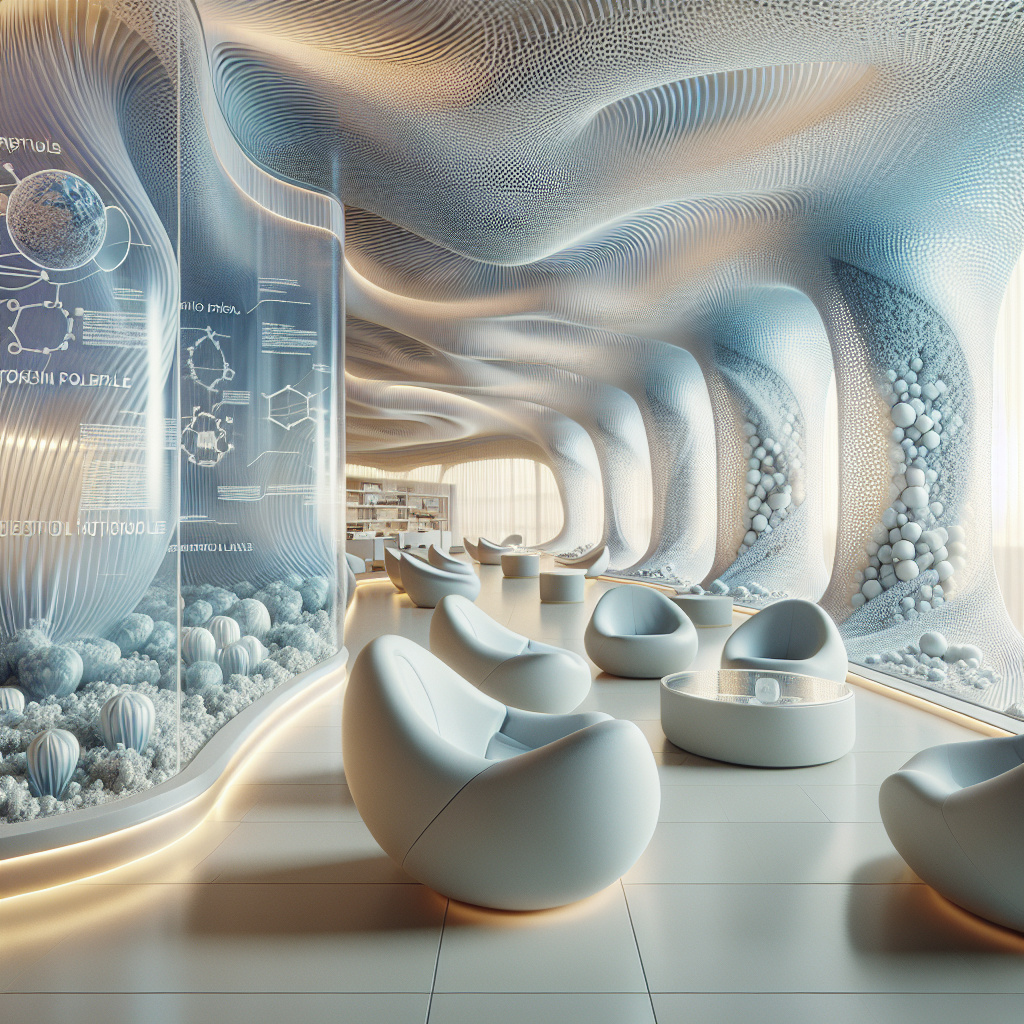

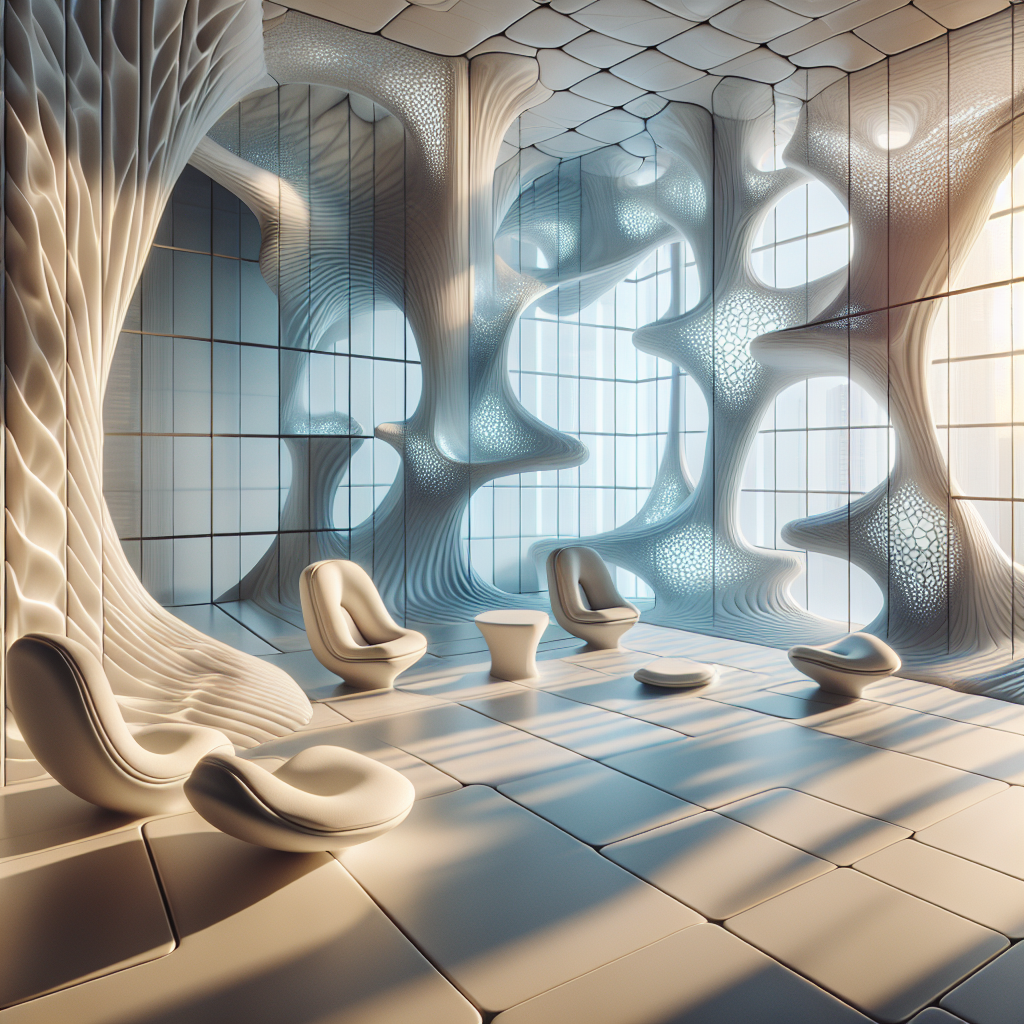

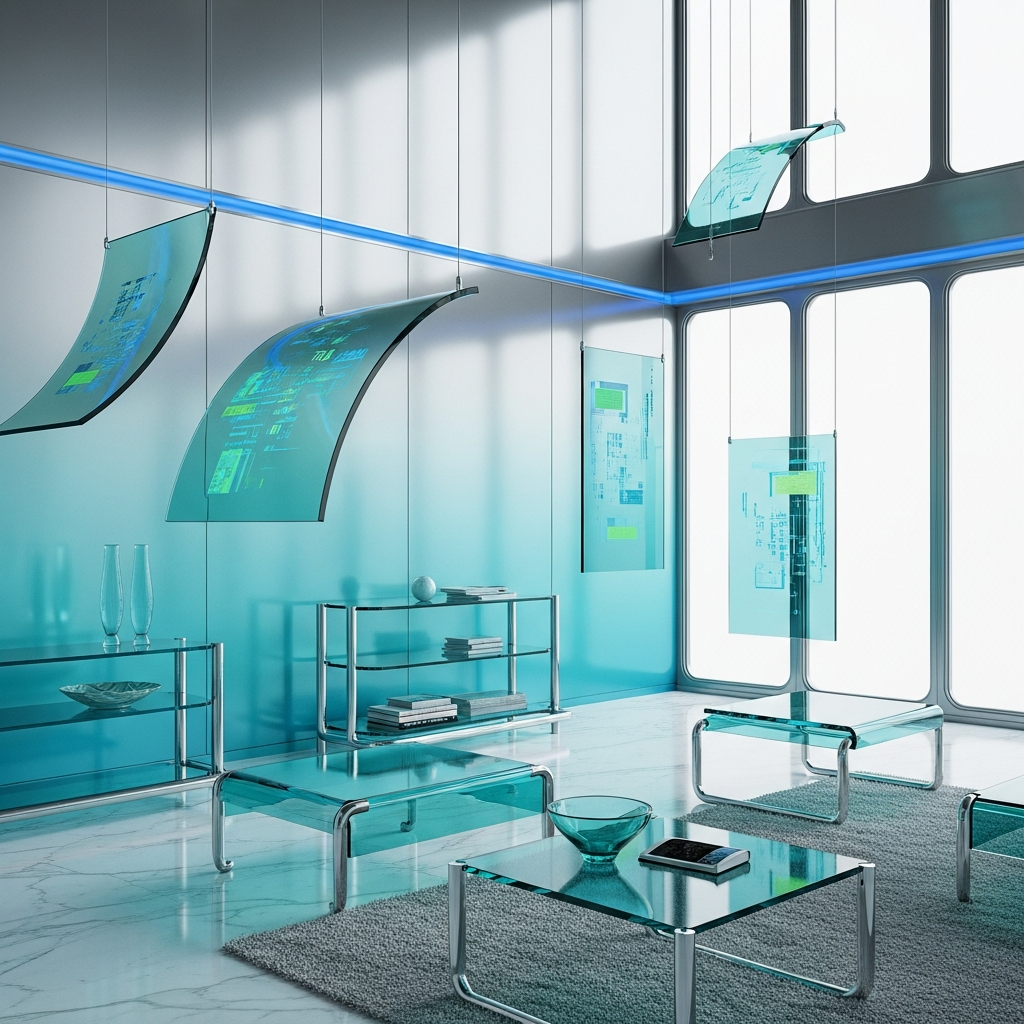

Imagine a wall that subtly bends when a door slams, absorbing the kinetic energy instead of transmitting sound or vibration. Or a seating system that molds to the user’s body and then gently reverts to its pristine form. Such designs embody the principles of responsive architecture—a field already explored in projects like adaptive interiors and kinetic facades. Yet, 3D-printed cartilage materials bring this adaptability to a micro level, embedding flexibility directly into the fabric of the space.

3D Printing: The Bridge Between Biology and Design

The advent of 3D bioprinting has revolutionized material science, enabling the precise layering of polymers and biological analogues to replicate complex tissue structures. In design, this technology translates into the ability to fabricate customized, gradient materials—soft in some areas, rigid in others—mirroring the heterogeneity of natural cartilage. This level of control allows architects to design surfaces that respond differently across their geometry, creating tactile, interactive environments.

Studios such as London-based ecoLogicStudio and MIT’s Mediated Matter Group have already experimented with biofabricated structures that integrate living organisms or bio-inspired geometries. The next logical step is to scale these innovations into interior applications: acoustic panels that flex like eardrums, partition walls that absorb impact like joints, or flooring systems that compress and rebound like ligaments. These designs not only redefine comfort but also reduce material fatigue, extending the lifespan of interior components.

Flexible Interiors: The Future of Spatial Adaptability

The concept of flexibility in interiors is not new—modular furniture, movable partitions, and transformable layouts have long catered to changing needs. Yet, the integration of cartilage-inspired materials introduces a new dimension: structural flexibility. Instead of relying on mechanical systems, the material itself becomes the mechanism of change.

In high-end hospitality or retail environments, for instance, 3D-printed cartilage composites could form dynamic wall systems that subtly shift to guide circulation or alter acoustics during different times of day. In residential settings, these materials could be used in adaptive seating or acoustic ceiling panels that respond to sound intensity, creating serene environments for relaxation or concentration. This echoes the growing movement toward biophilic design, where materials and forms evoke natural processes to enhance well-being.

Material Intelligence and Sustainability

Beyond aesthetics and adaptability, 3D-printed cartilage materials also hold promise for sustainability. Many of these composites can be produced using bio-based polymers or recycled materials, aligning with the principles of the circular economy. Their inherent flexibility reduces the need for replacement, while their self-healing potential minimizes waste over time.

Moreover, the localized nature of 3D printing supports on-demand production, eliminating the carbon footprint associated with mass manufacturing and transportation. As architects increasingly embrace digital fabrication and additive manufacturing, cartilage-inspired materials could become a cornerstone of sustainable, adaptive design ecosystems.

Case Studies: From Concept to Prototype

Several experimental projects have begun to explore the potential of cartilage-like materials in design. At ETH Zurich, researchers have developed hydrogel-based composites that can be 3D-printed into flexible, load-bearing structures. These materials exhibit mechanical behaviors similar to biological cartilage, offering unprecedented resilience and softness in architectural applications.

Meanwhile, the Milan-based studio Carlo Ratti Associati has experimented with responsive furniture systems that adjust their form through embedded sensors and flexible materials. While not explicitly cartilage-based, these projects hint at a future where interiors are no longer static but instead alive with movement—capable of adapting to users’ rhythms, postures, and moods.

In the luxury retail sector, conceptual installations have already showcased walls that “breathe” through subtle undulations, creating immersive environments that respond to human proximity. These kinetic, cartilage-inspired systems redefine the sensory experience of space, blurring the line between architecture and organism.

Challenges and Ethical Considerations

As with any emerging technology, the integration of bio-inspired materials raises questions about durability, maintenance, and ethics. While synthetic cartilage analogues are non-biological, their resemblance to living tissue prompts reflection on the boundaries between organic and artificial. Designers must balance innovation with responsibility, ensuring that such materials remain safe, recyclable, and contextually appropriate.

There are also technical challenges: achieving consistent mechanical performance, preventing material degradation, and ensuring scalability for large architectural applications. Yet, these obstacles are reminiscent of early skepticism toward concrete or carbon fiber—materials that eventually redefined modern architecture.

Designing for a Living Future

The emergence of 3D-printed cartilage in design signals a deeper philosophical shift. It challenges the long-held notion of architecture as static and immutable, inviting us to imagine spaces that evolve, heal, and respond like living systems. In this sense, biomimicry becomes not just a design strategy but a worldview—one that sees buildings as participants in ecological and human networks rather than isolated objects.

In the coming years, as material science continues to merge with computational design, we may witness interiors that move with us, listen to us, and care for us. The cartilage-inspired paradigm embodies this future: soft yet strong, flexible yet enduring, profoundly human in its responsiveness. It is architecture’s quiet evolution—one that bends, not breaks, in the face of change.

For designers and architects seeking to push the boundaries of material innovation, the lessons of cartilage are clear: flexibility is not weakness, but wisdom. And in a world increasingly defined by volatility, the most resilient spaces may be those that, like living tissue, know how to adapt.

Keywords: 3D-printed cartilage, biomimicry in design, flexible interiors, adaptive architecture, sustainable materials, responsive design, digital fabrication.